MotionSolve™

What is Altair MotionSolve?

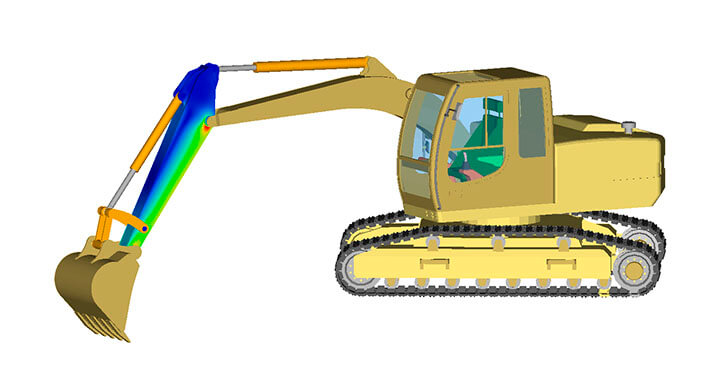

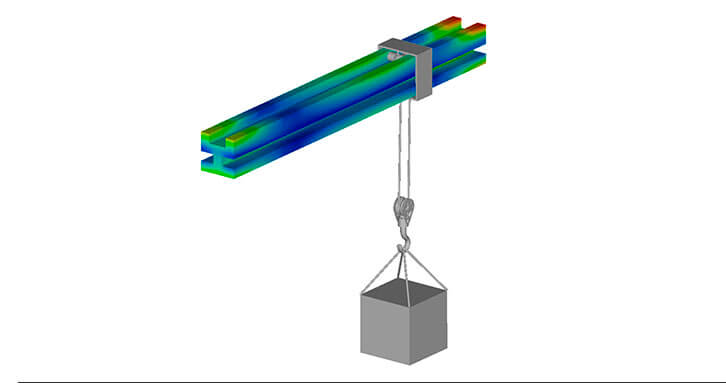

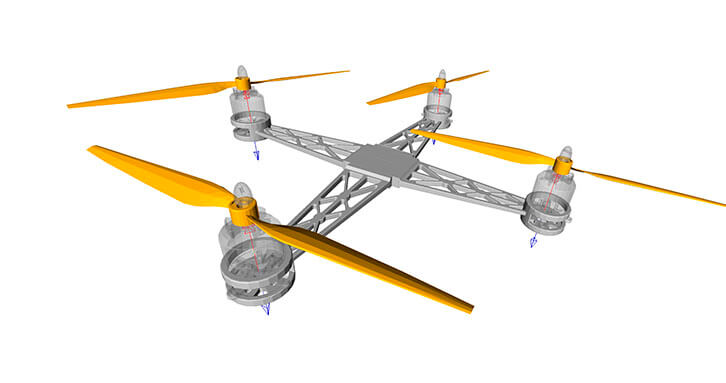

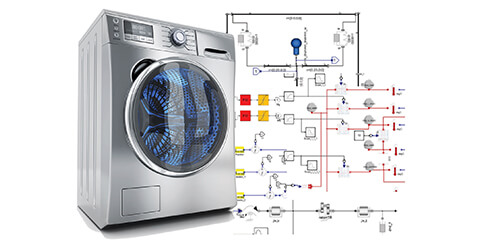

MotionSolve performs 3D multi-body system simulations to predict the dynamic response and optimize the performance of products that move.

By considering realistic motion-induced loads and environmental effects, engineers and designers can be confident that their products, when made and operated, will perform reliably, meet durability requirements, and not vibrate excessively or fail from fatigue. As a tool for simulating ever-smarter products as systems-of-systems, MotionSolve facilitates multi-disciplinary collaboration across product development teams. For example, it enables the combined simulation of subsystems for mechanical plants together with those for electrical/electronic subsystems (e.g., controllers).

As a way of significantly reducing expensive prototype-builds and physical testing, MotionSolve is cost-effective and an essential part of the Altair HyperWorks™ suite of multiphysics CAE tools available via Altair’s patented units-based licensing. See also the Motion module included with Altair Inspire™.

Why MotionSolve?

Ensure Desired System Performance

Be sure products move as intended before building them. Study design variations with ease. Use real component loadings for strength and fatigue calculations.

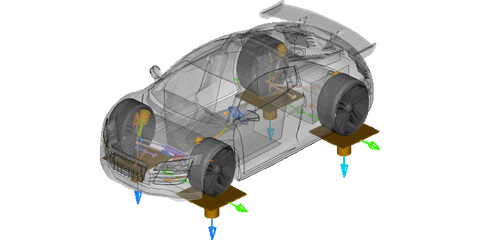

Accelerate Vehicle Development

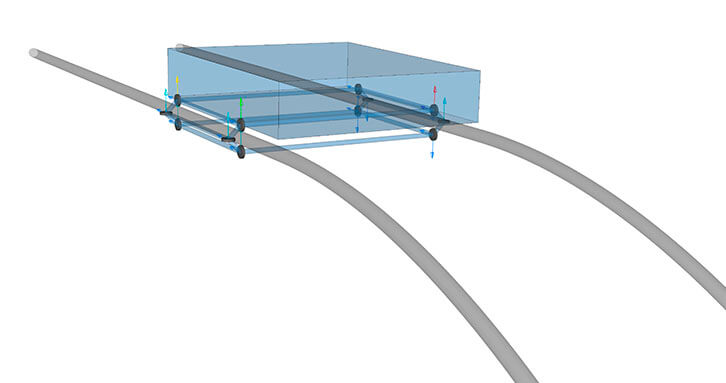

Assemble detailed, parametric vehicle models with ease. Test them as you would in the real world. Improve their performance. Understand the design trade-offs.

Understand and Improve Real-World Systems

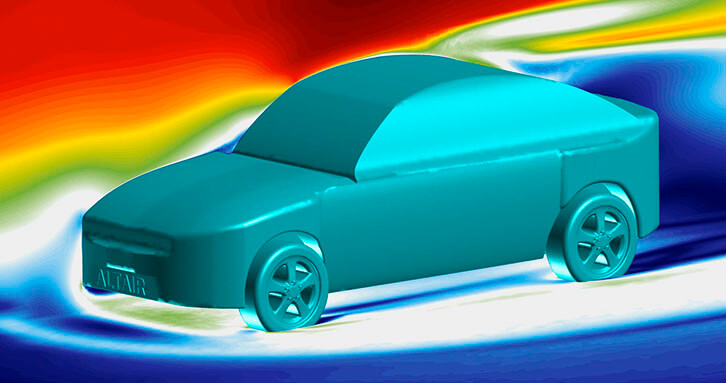

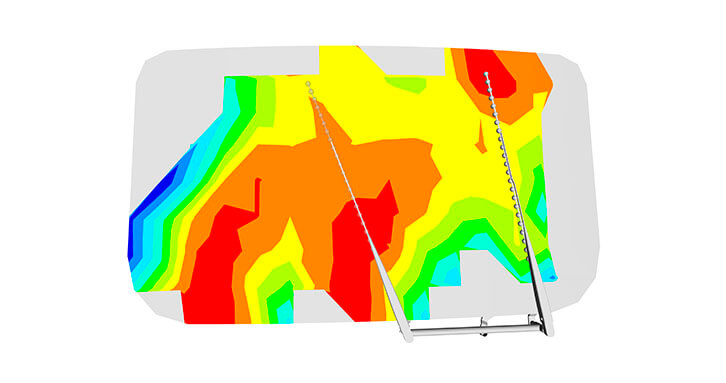

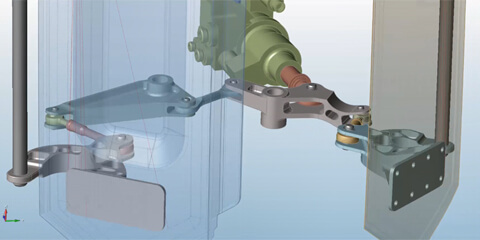

Combine Motion with FEA tools to import flexible bodies and export operational loads; with 1D tools for multi-disciplinary system simulations (mechatronics); with CFD for fluid effects (aerodynamics or sloshing); etc.

Key Features

Animate assemblies and plot measured data to obtain useful insight about product performance from a motion perspective.

Readily import 3D part geometry, positions, and mass properties from preferred CAD tools to accurately predict forces and dynamic movements of all parts in the system.

In contrast to physical prototypes, extract valuable measurement data at any location in or on a virtual prototype.

Include complex phenomena such as tire-road interactions, chains or belts, generalized contacts, discrete element modeling (DEM), hydraulics, controllers, and more.

For key model parameters, simply replace numbers with variables to enable faster “What if…?” type design exploration and optimization.

Through continually tested and enhanced solver technologies, MotionSolve rapidly delivers reliable motion simulation results.