Inspire

What is Inspire?

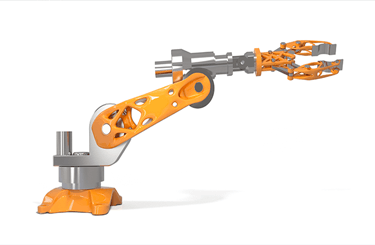

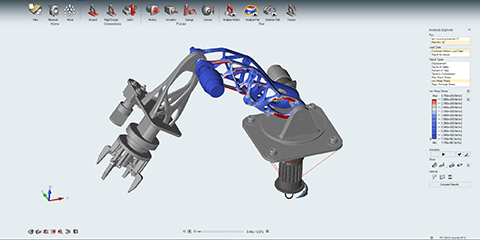

Applied early in the product development lifecycle, Inspire accelerates the creation, optimization, and study of innovative, structurally efficient parts and assemblies through collaboration. Inspire's award winning user experience for geometry creation and modification can be learned in just a few hours, and delivers dependable Altair solver power:

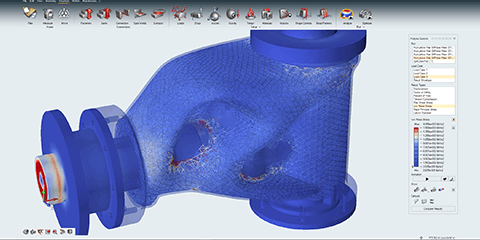

- Structural analysis with the speed & accuracy of Altair SimSolid™ - as independently validated by NAFEMS - provides the ability to analyze large assemblies & complex parts.

- Dynamic motion simulation, including loads extraction, using the reliable multi-body systems analysis of Altair MotionSolve™.

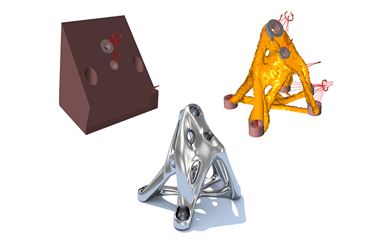

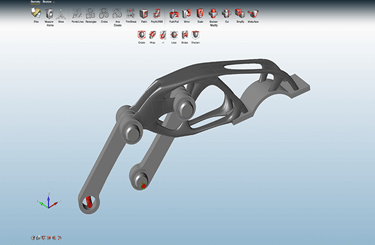

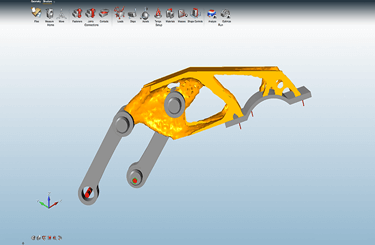

- The industry standard for structural efficiency, topology optimization by Altair OptiStruct™, for the generative design of practical, viable, and manufacturable geometry.

Inspire enables both simulation analysts and designers to perform what-if studies faster, easier, and above all earlier, encouraging collaboration and reducing product time to market.

Why Altair Inspire?

Create and Modify Designs with Ease

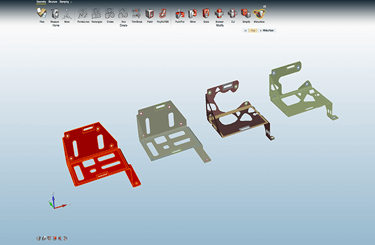

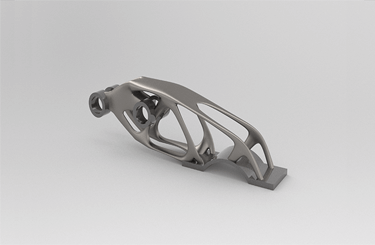

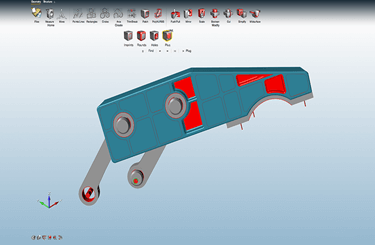

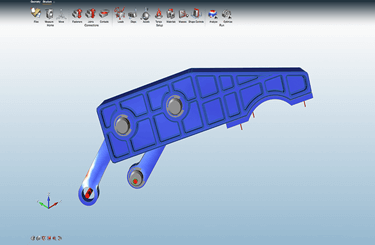

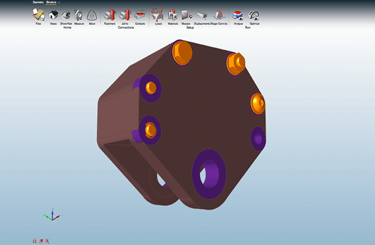

Create, modify, and defeature solid models quickly, use PolyNURBS to create free-form smooth geometry, and study multiple assembly configurations.

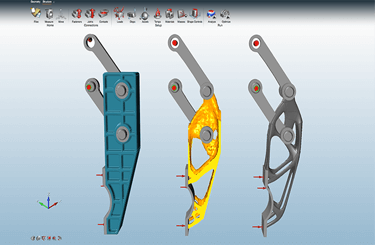

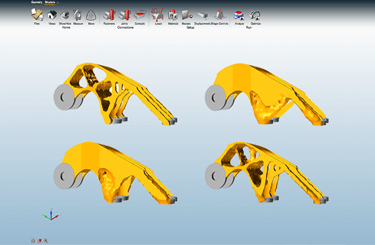

Optimize for Manufacturability

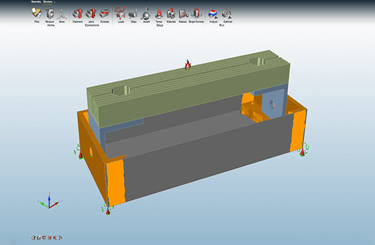

Arrive at the ideal design direction extremely early in the process: topology optimization is based on physics and observes manufacturing process constraints.

Simulate at the Speed of Design

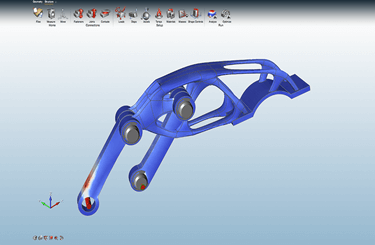

Experience an interactive engineering design environment for rapid design exploration and product creation, without the need to invest in new computer hardware.

Key Features

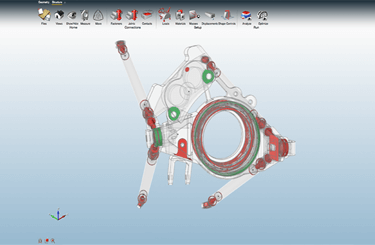

Create, modify, and de-feature solid models using Inspire's modeling tools. Leverage the speed and accuracy of SimSolid to evaluate multiple variants.

Easily generate dynamic motion of complex mechanisms, automatically identifying contacts, joints, springs, and dampers.

Inspire offers a number of topology options including: optimization objectives, stress and displacement constraints, acceleration, gravity, and temperature loading conditions.

Design for additive manufacturing with overhang shape controls to help reduce overhangs to create more self-supporting structures.

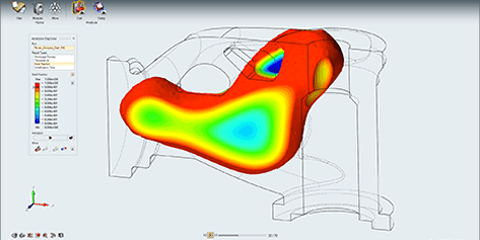

Investigate linear static and normal modes analysis on a model and visualize displacement, factor of safety, percent of yield, tension and compression, von Mises stress, and major principal stress.

Create multiple assembly configurations which can then be used to evaluate various design scenarios and the resulting concepts.